Unique technology hidden behind the beautiful shapeWALL V Series

The “WALL INTERIOR TV STAND” blends in with the environment and enhances it.

The simple and attractive appearance of our product is the result of countless trial and error experimentation by our designers and engineers and is brimful of original ideas and technology.

It all started with one wall-mounted TV

The occasion was the “Milano Salone”, one of the world’s largest interior fair held in Milan, Italy. Our delegation team took a glimpse of a “wall-mounted TV” and wondered its picturesque beauty. This encounter became the source and inspiration for developing the WALL series products.

At that time, the idea of merging the TV with other interior objects was yet nowhere to be seen. The encounter gave a deep impression to our engineers who were searching new themes of development: “Our lives could become much more exciting if we could place the TV in a variety of locations freely”

Mounting the TV on the wall seemed to be the ultimate style, especially for installing large TVs without taking up room space. On the downside, wall mounting is associated with cumbersome installation issues such as drilling holes in the wall for fixing and cable routing. In addition to it, the user may find if difficult to prepare site for peripheral devices. All the delegation members came to share the desire to develop : “TV stands that unite the functionality of wall mounting and beauty of interior objects that brighten up the room, and they should allow easy setting up in any place int the room”. On return to Japan, the delegation members delivered their passionate message to the development team. A journey to uncharted territory thus started.

Screw hole dilemma

TV stands were already seen occasionally at that time. But most of them were designed for industrial use and certainly not something “you would want in your living room”.

To attain the level of beauty as an interior object, uncompromised attention to details is essential.

For example, redundant “screws” and “holes” should not be visible from the front.

In the development of WALL series, minimal design and avoidance of redundant elements were of utmost priority.

Having said that, screws and holes can not be totally eliminated if a shelf is to be attached to the stand.

There is no easy way to eliminate them.

And this dilemma led to another problem.

Because the screw hole positions are predetermined, these positionings may hinder the users to attach the shelf at the exact height they want.

Single screw hole can prevent ideal positioning, in spite of the money they invested on it.

Such inconveniences must be removed.

What if we abandon the idea of using “holes” to fasten objects?

Would that even be possible?

A totally unconventional approach

Abandoning the use of “holes" to fasten object to achieve a good balance between appearance and functionality!

This seemingly impossibly challenge can only be solved through an out-of-the-box thinking. The development team was working hard to find a method to fasten objects without using “holes”.

Finally they arrived at an idea “press fastening”: i.e. installing a special bar inside the shelf and press it against the post to render immovable.

As this method does not require screw holes, screw heads are eliminated from the frontal view. Thus the shelves can be attached at an arbitrary height without damaging simple and beautiful appearance. The team was totally delighted when the prototype was completed after an extensive trial and error process. A utility model right was granted to this novel fixing method, which further spurred the team toward fulfilling its dream.

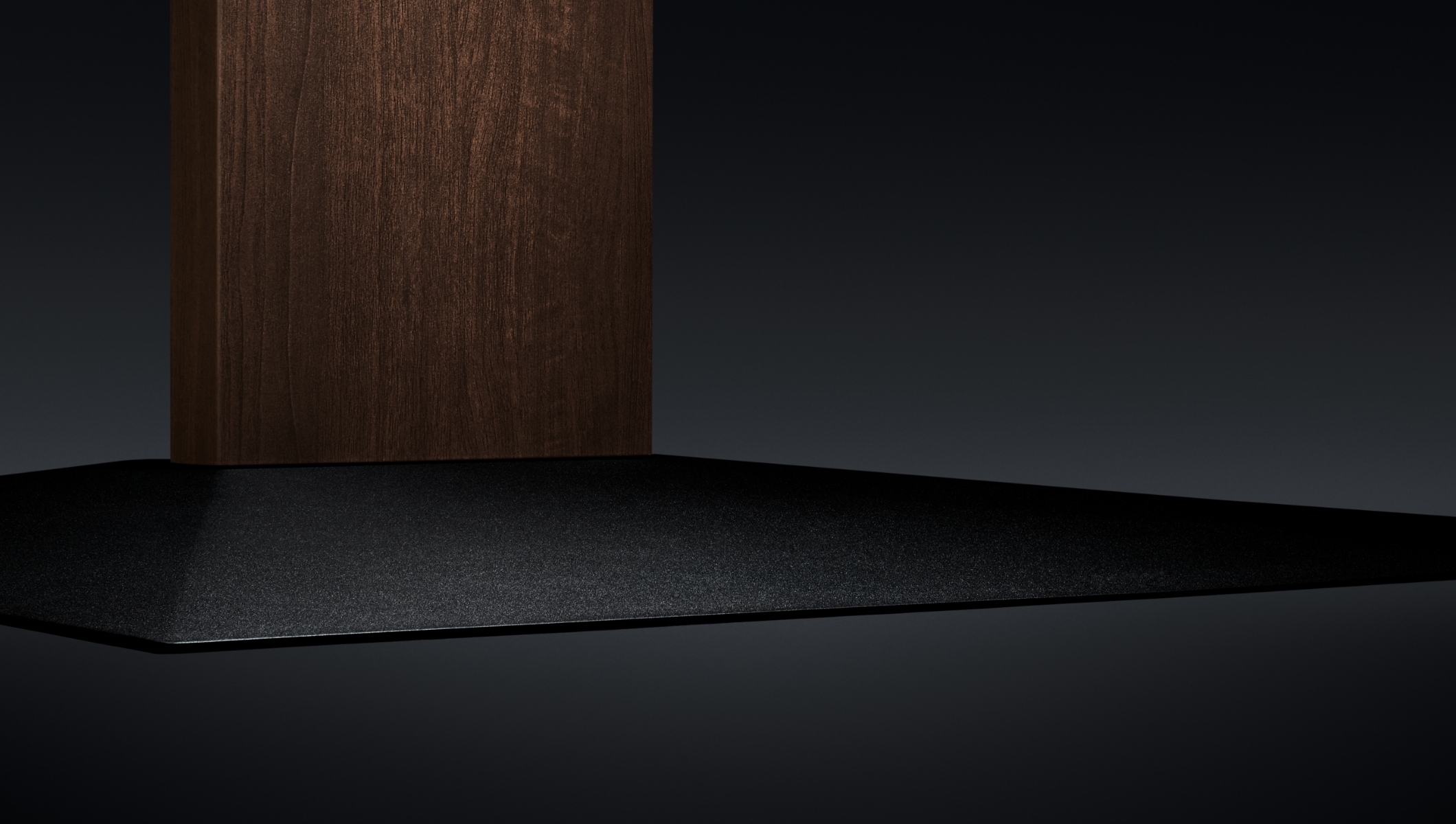

Challenge of thinning down the base to “2 mm (0.08 inch)”

The “base” of the stand, which is placed on the floor, plays a critical role to withstand the heavy weight of the TV. However, if the base is too large or thick, it may not only damage the stylishness of the stand, but also presents the danger of impairing safety. Even a small step on the floor can cause stumbling.

Wherever the stand is placed in the room, it should provide free and safe movement of the people, without interfering with their passages. We wanted to develop a product we can deliver with utmost confidence. To achieve this goal, we needed a help from external expert.

Consultation with an architect (a first-class registered architect) revealed that “senior members and children can stumble to a step as low as 5 mm (0.2 inch) on the hallway floor they are used to come and go in their daily life”.

How thin it should be? After repeated trials to find out an adequate thickness of the base, we reached the conclusion that it should be around 2 mm (0.08 inch) or less.

However, an iron plate with 2 mm (0.08 inch) thickness cannot provide the strength to support the TV.

After a lot of prototyping, we came to a design in which an iron plate is bended in low-profile pyramidal form and the TV supporting pole is situated in the highest position in the center. To secure rigidity, radially spreading reinforcement elements (like the shape of a hand) was arranged on the bottom side of the base. The interior TV stand thus completed proved the ability to withstand an earthquake up to level 7, while maintaining its flat and smart appearance.

The challenges did not stop there

The dream we envisioned in Milano thus came to reality.

However, our challenge to create “products not to be found anywhere” does not stop here. Lifestyle will keep changing and so the needs for TVs and TV stands. We still have a lot of room ahead of us to keep up with these needs toward well-heeled life with the TV. WALL series will keep on evolving, with our persisting passion, to create products you have never seen before.

Planning and Development Group, NAKAMURA Co. Ltd.

Taishi Tozawa : Industrial designer

After graduating from graduate school in 2004, Mr. Tozawa joined a toy manufacturing company, where he engaged mainly in structural design. He joined NAKAMURA Co. Ltd. in 2012. He is one of the original members of WALL TV stand development group, and continues to be so up to the present.

PRODUCT LINE UPIntroducing the full lineup of the V Series

-

V4 FLOOR TYPE

Special model for up to 90 inch large TVs.

-

POPULAR MODELS

POPULAR MODELSV3 HIGH TYPE / LOW TYPE

High specification model for 32 to 80 inch TVs.

-

NEWCASTER MODELS

NEWCASTER MODELSV2 CASTER HIGH TYPE / LOW TYPE

A free-standing model with ultra-low floor casters accommodating up to 60 inch TVs.

-

V2 LOW TYPE

Entry model accommodating up to 60 inch TVs.

-

CASTER MODELS

CASTER MODELSV5 HIGH TYPE / LOW TYPE

Model with ultra-low floor casters accommodating up to 80 inch TVs.